Mechanical engineers play a vital role in the manufacturing industry. They are responsible for designing, analyzing, and improving mechanical systems used in various manufacturing processes. Their expertise spans a wide range of areas, including product design, production techniques, and system optimization. In this article, we will explore the role of a mechanical engineer in manufacturing, the key responsibilities, and how their contributions impact the production process.

What is a Mechanical Engineer?

A mechanical engineer is a professional who specializes in the design, analysis, and manufacturing of mechanical systems. These systems can include engines, machines, tools, and devices that are used across a variety of industries, including automotive, aerospace, robotics, and energy. Mechanical engineers work closely with other engineers, technicians, and designers to ensure that systems are not only functional but also efficient and cost-effective.

In the context of manufacturing, a mechanical engineer plays a crucial role in ensuring the quality and efficiency of the production process. From the initial design phase to the final product, mechanical engineers are involved in every stage of manufacturing, helping to optimize resources, improve performance, and ensure safety standards are met.

The Responsibilities of a Mechanical Engineer in Manufacturing

1. Product Design and Development

One of the primary responsibilities of a mechanical engineer in manufacturing is product design. They are involved in conceptualizing new products, creating blueprints, and determining how these products can be manufactured efficiently. A mechanical engineer uses various design tools, such as CAD (computer-aided design) software, to create precise models and prototypes. They ensure that the design is practical, manufacturable, and cost-effective.

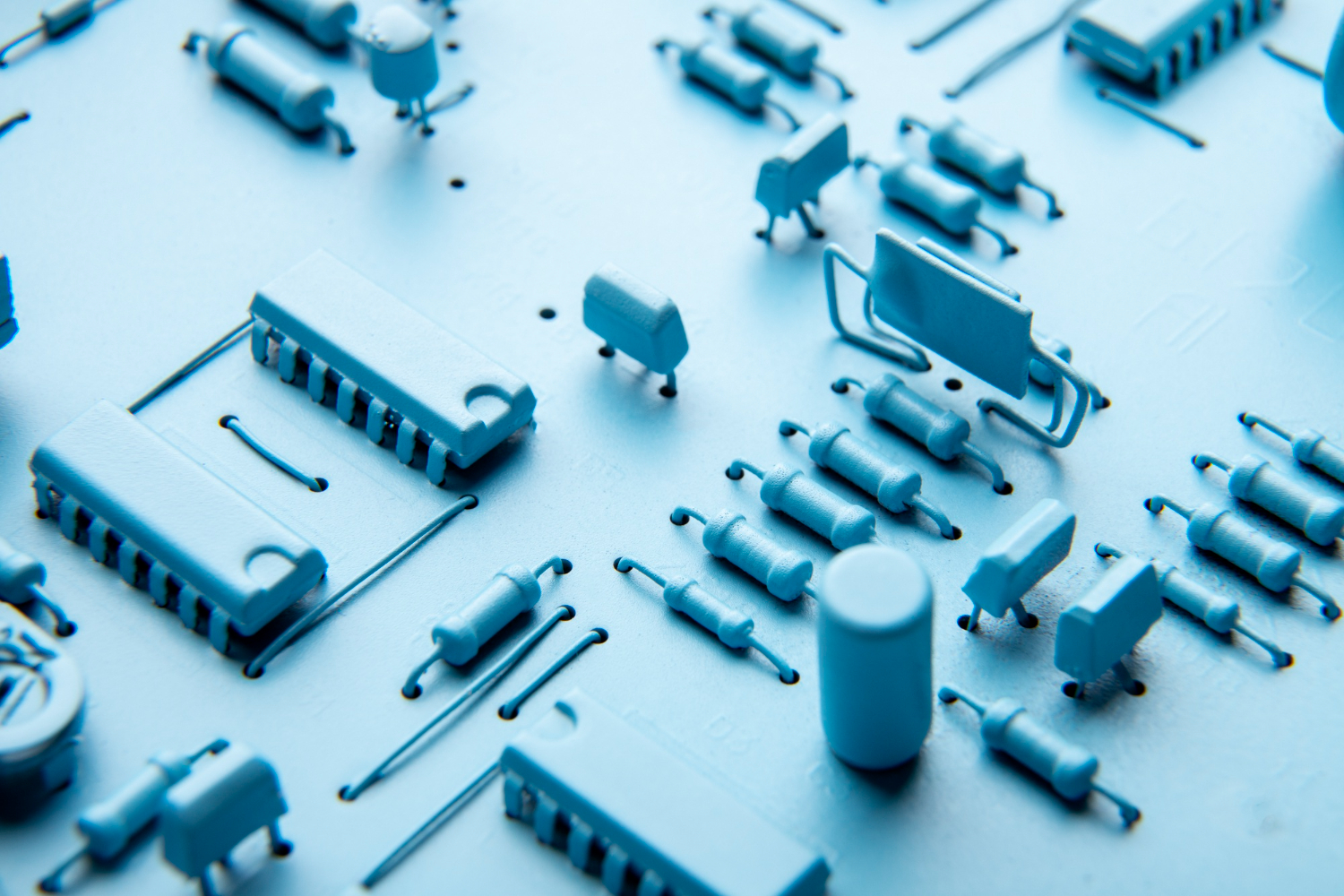

2. Selecting Materials and Manufacturing Processes

Once the design is completed, a mechanical engineer selects the appropriate materials for production. The choice of materials is crucial, as it directly impacts the performance, durability, and cost of the final product. For example, in the automotive industry, the material selection for engine components must meet strict standards for heat resistance, strength, and weight. The mechanical engineer also decides on the most suitable manufacturing processes, whether it’s casting, machining, injection molding, or additive manufacturing.

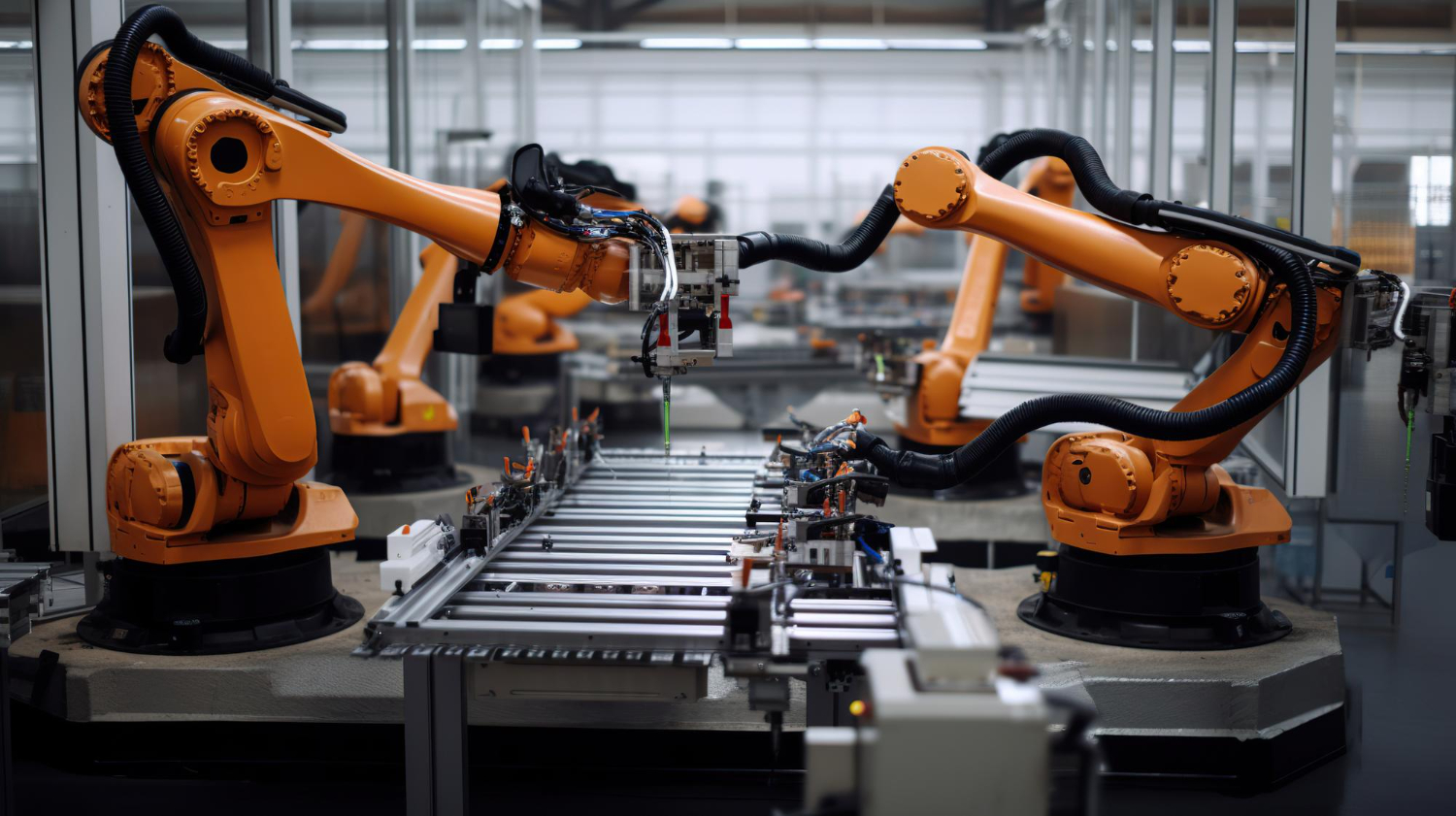

3. Process Optimization

In manufacturing, process optimization is essential for improving efficiency, reducing costs, and ensuring high-quality products. Mechanical engineers continuously assess the manufacturing process to identify areas for improvement. This could involve analyzing production lines, eliminating bottlenecks, enhancing machine performance, or introducing automation to speed up repetitive tasks. Their goal is to make the production process smoother, faster, and more cost-efficient while maintaining quality standards.

4. Testing and Quality Control

A mechanical engineer plays a crucial role in testing and quality control within the manufacturing environment. After the product has been manufactured, engineers conduct rigorous tests to ensure that it meets the required specifications and standards. This involves performing stress tests, durability tests, and other forms of quality assurance to identify any potential weaknesses or defects in the product. Quality control is vital to ensure that the final product is safe for consumers and performs as expected.

5. Maintenance and Repair

Once a product has been manufactured and is in use, the mechanical engineer is often responsible for maintaining the equipment and machinery used in the production process. Regular maintenance is crucial to keep the machinery running efficiently and prevent costly breakdowns. In case of equipment failure, mechanical engineers are called upon to troubleshoot the problem, make repairs, and implement improvements to prevent future issues.

6. Collaboration with Other Teams

Mechanical engineers work closely with other professionals in the manufacturing industry, such as electrical engineers, industrial engineers, and production managers. Effective communication and collaboration are key to achieving the desired outcome for any manufacturing project. By working together, engineers can optimize systems, troubleshoot problems, and ensure that the final product meets both technical and customer requirements.

The Importance of a Mechanical Engineer in Manufacturing

Mechanical engineers are essential to the manufacturing process because they provide the technical expertise needed to bring products from concept to reality. Their work influences nearly every aspect of production, from the design and material selection to the optimization of processes and the final testing. Without mechanical engineers, it would be difficult to produce high-quality products that are both functional and efficient.

Additionally, mechanical engineers contribute to the advancement of technology in manufacturing. As industries evolve, the demand for innovative solutions grows, and mechanical engineers are at the forefront of creating new technologies and processes. Whether it’s developing more energy-efficient machines, implementing automation, or introducing sustainable manufacturing practices, mechanical engineers play a pivotal role in shaping the future of manufacturing.

Conclusion

In conclusion, the role of a mechanical engineer in manufacturing is multifaceted and crucial to the success of any production process. From designing products and selecting materials to optimizing manufacturing processes and ensuring quality control, mechanical engineers are involved in every stage of production. Their technical expertise is vital for improving efficiency, reducing costs, and maintaining high-quality standards. By continuously pushing the boundaries of innovation, mechanical engineers help drive the manufacturing industry forward.

If you’re looking for professional mechanical engineering solutions and services, you can rely on HDE. With a proven track record in delivering high-quality services and products, HDE continues to be a leading player in the industry, providing cutting-edge engineering solutions for various manufacturing needs.